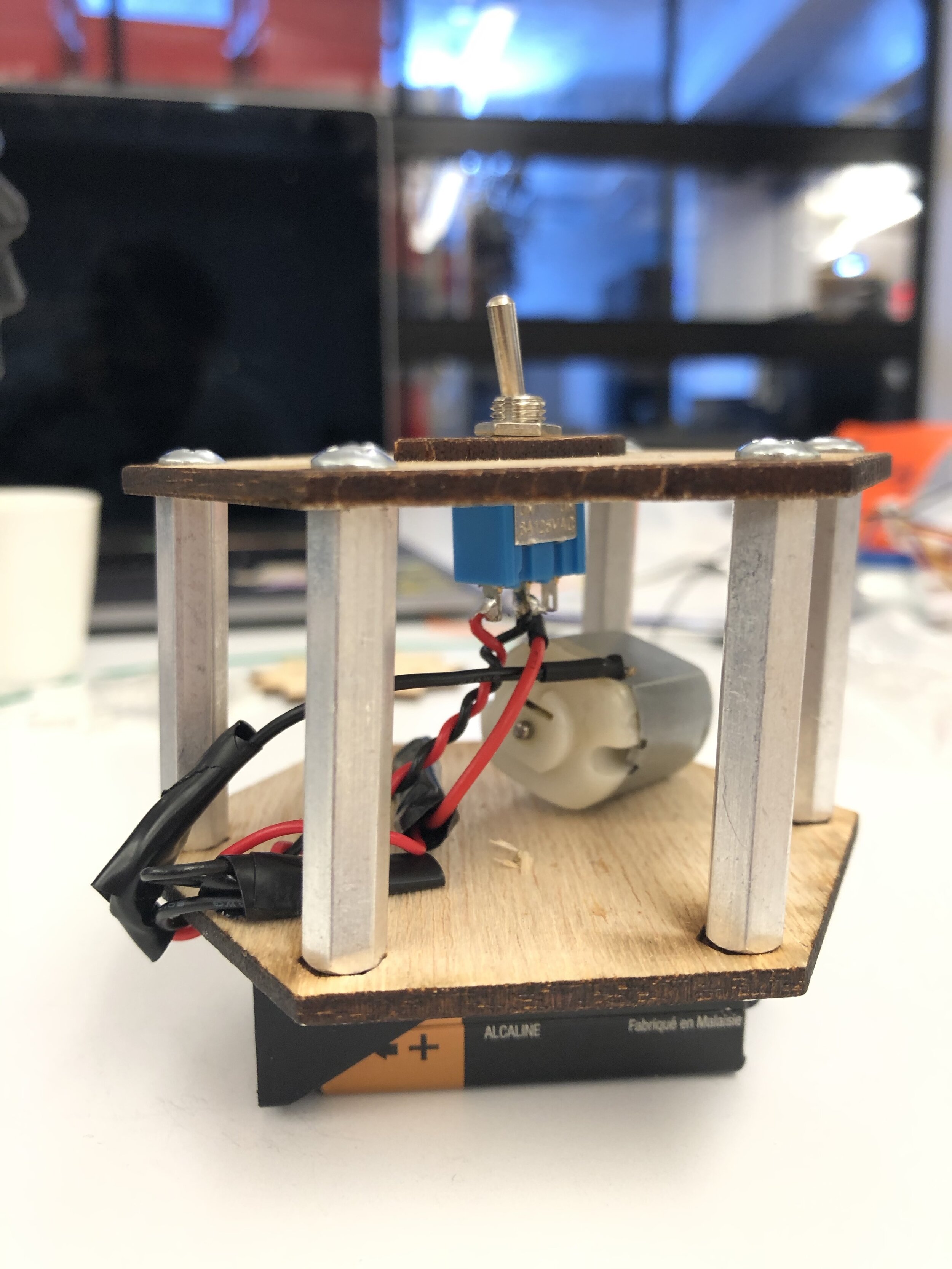

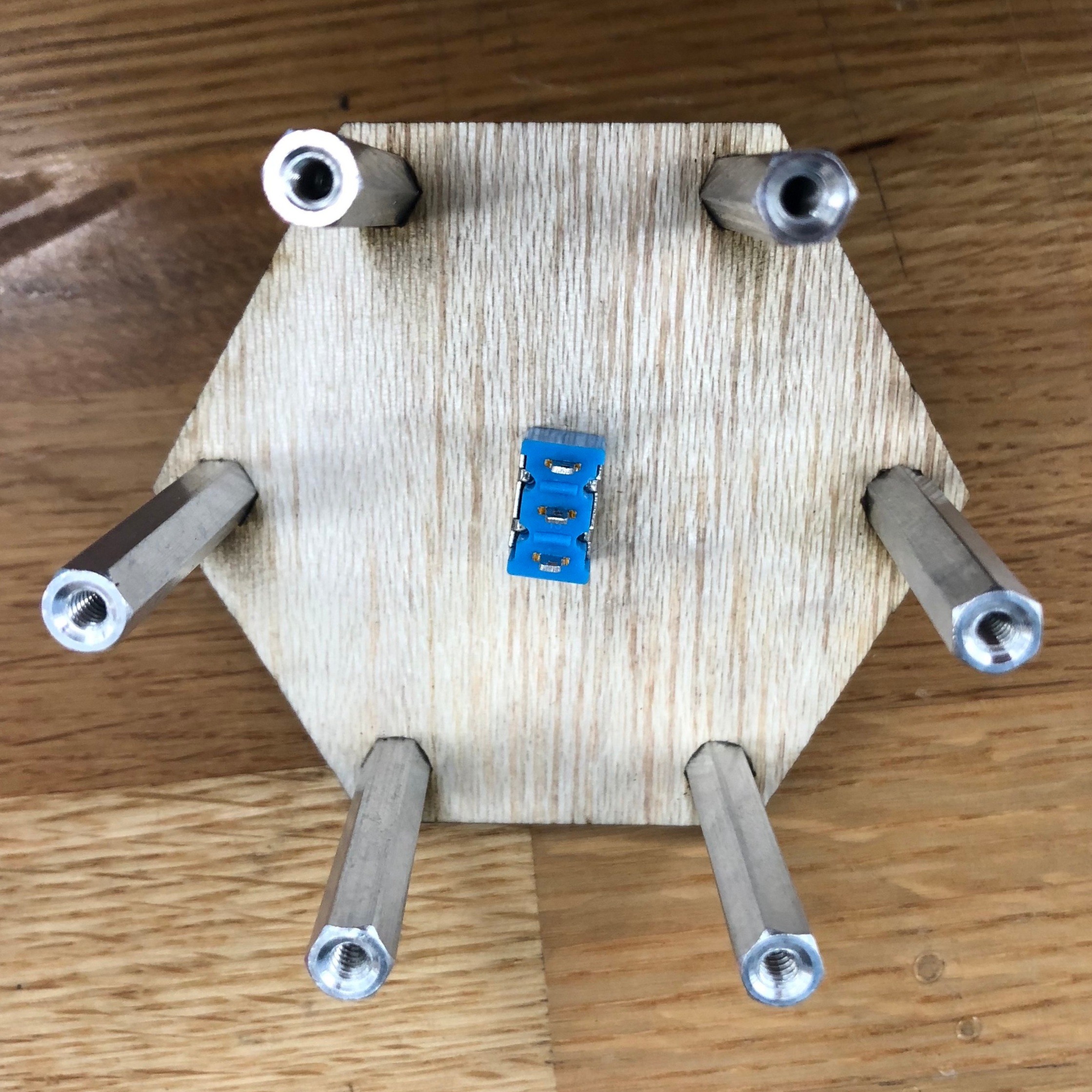

This week, I attached a motor to the enclosure without a purpose to give it a purpose. To do this, I found a DC motor from my Arduino kit from last year and I gathered the necessary materials, and purchased a 9v battery holder and screws from Tinkersphere. I used a cardboard cutout of the star from my first project; and assembled per the below steps;

1a. marked holes of base of wood enclosure

used a pointed object (sharp tweezers in this case) to make markers matching the battery holder below

1b. 9v battery holder

used to make markers in wood enclosure

2a. hand drill with 1/16” bit

drilled holes for brass wood screws

2b. drilled holes in markers

using hand drill with 1/16” bit

3a. brass wood screws

used to fasten 9v battery holder to wood enclosure

3b. 9v battery holder

fastened to wood enclosure

4. solder wires to switch and power source

5. solder power source to motor

6. locate location for motor

7. application of hot glue to stabilize star to motor

8. application of hot glue to stabilize motor to wooden enclosure

project, complete.

orientation designed for a hand-held enclosure with switch to direct ‘on’ pointed towards moving star