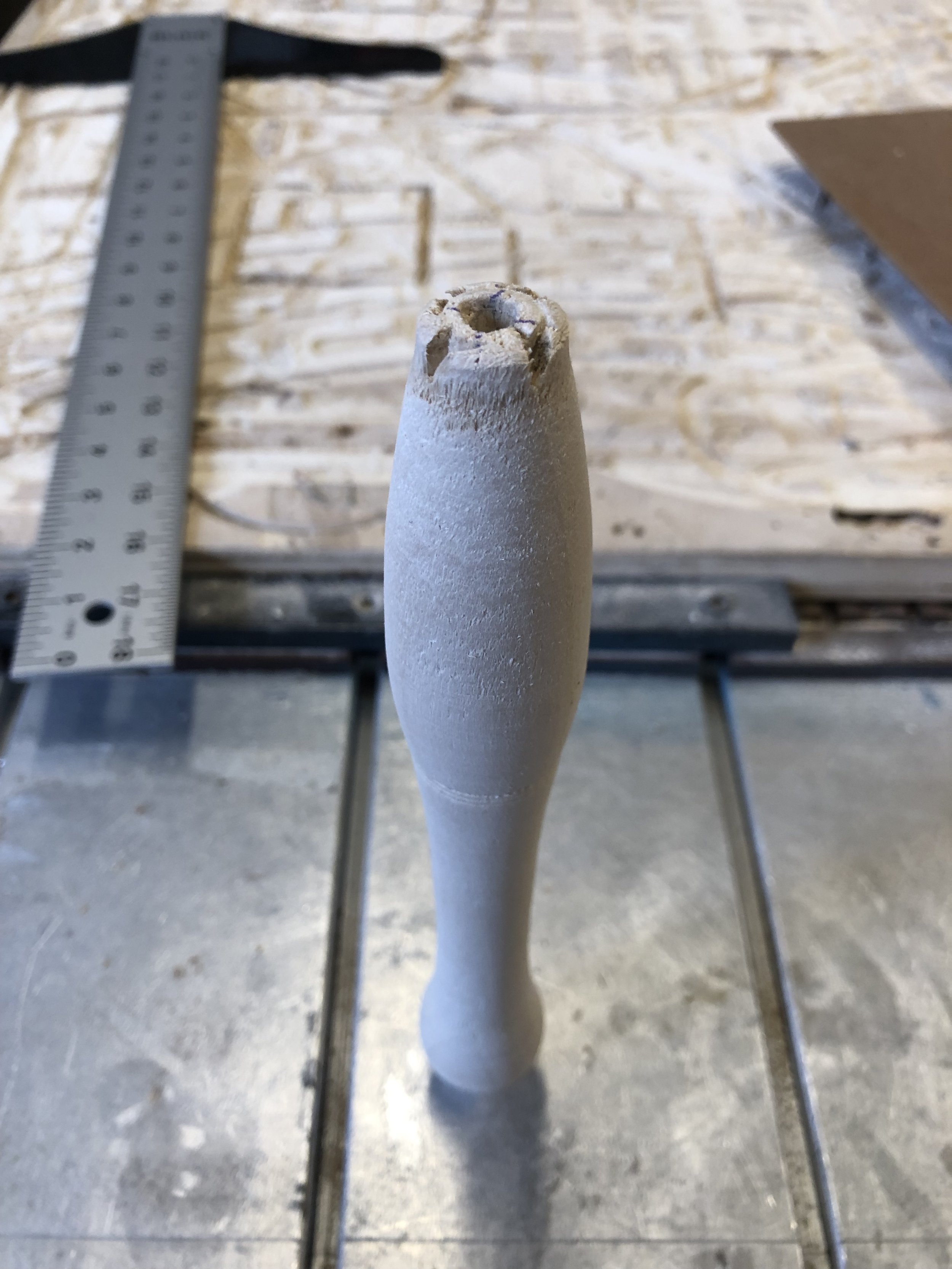

For the final, I decided to make a very low-tech game board for wood lathed tops to spin on. My experience using the wood lathe this semester has been incredible thus far and I very much so have enjoyed learning the process with different types of woods. One morning I woke up and decided that I would make a top. I chose to make this out of Poplar wood because I wanted to see how poplar turned and wanted to make something that I could fidget with that was not plastic. I also liked the natural greens that were in the wood and thought I’d try it out.

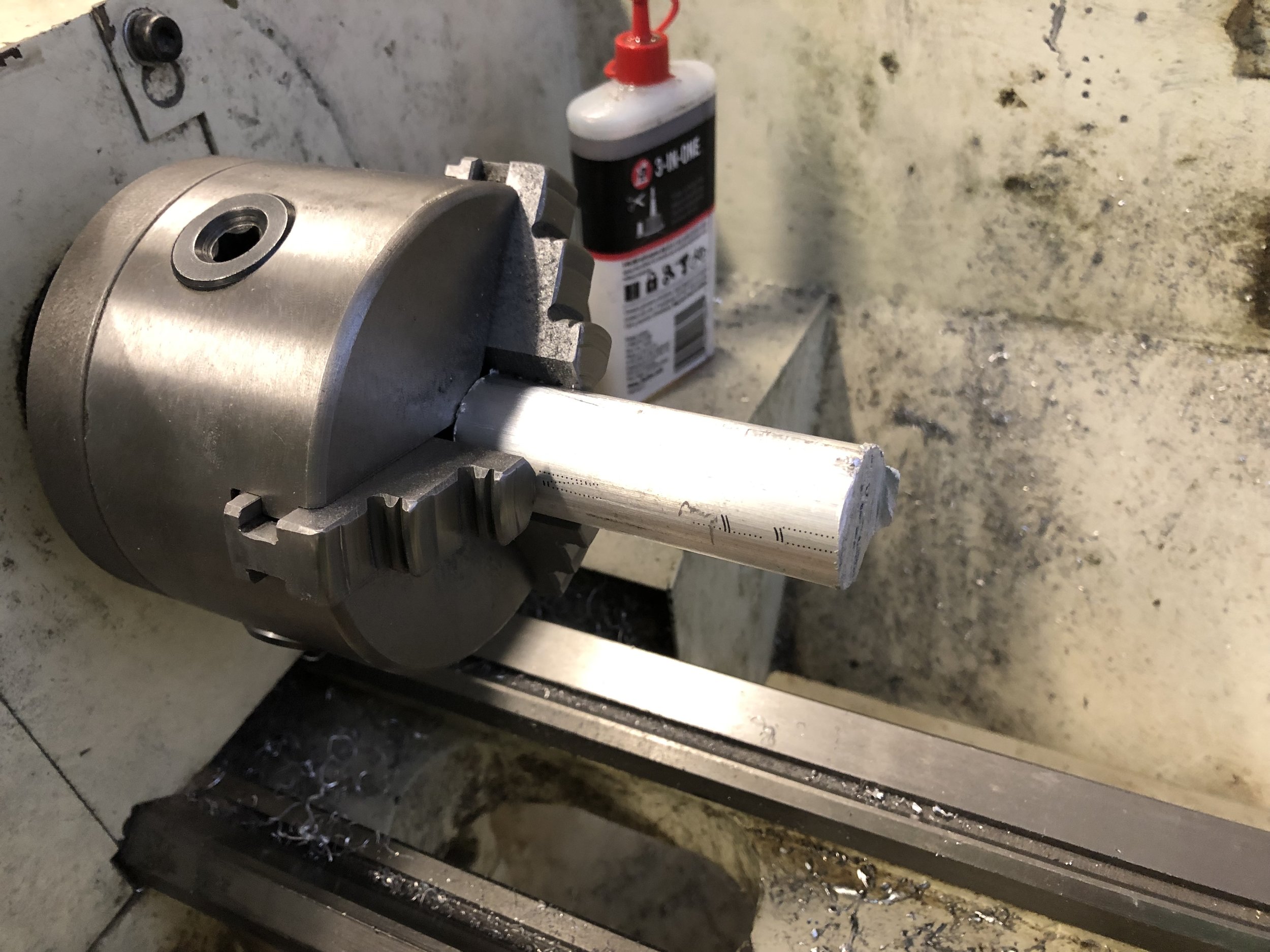

When I was turning the top I didn’t try to shape it too much or add too many details. It was my first time turning with Poplar and I wanted to get a hang of it, as I bought a bit of wood for the future to use. A big lesson I learned immediately was that the turning process is a bit tricky towards the end when creating the tip for it to spin on. With the poplar top, I decided to hand-sand the bottom to perfect the tip for a good spin and then had to clean up and run to class.

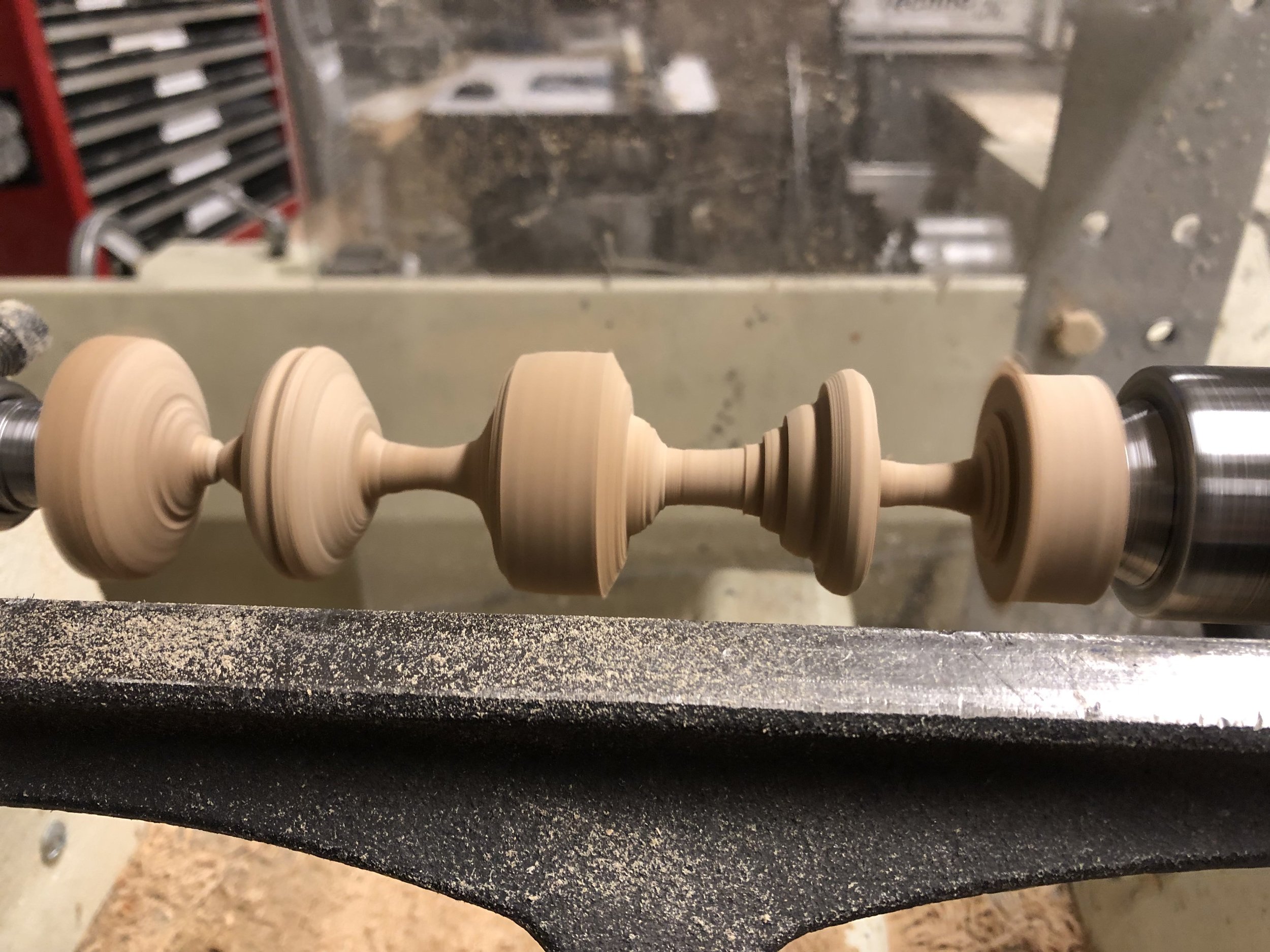

During class I kept playing with the top and wondered other woods would feel like. After class, I turned an additional two tops that evening — both made out of oak. These were more detailed and a bit unique in their own way. Oak was a bit more difficult to turn as it chips quite a bit, but I managed to get these two on the same piece at once. Again, turning the tips managed to be a challenge so I hand sanded them as well.

At this moment, I decided I wanted to do a series of tops for the final project. I had a bit of walnut still left from my mallet project and quickly spun up two tops — one larger and smaller than before. For good measure and practice, I also made another oak top. The tips are the vain of my existence at this point yet I use the sander with a gig and get some interesting results - there is no tip on the big walnut, a very pointy tip on the small walnut, and burned marks on the oak. A mix for sure, but each unique in their own way.

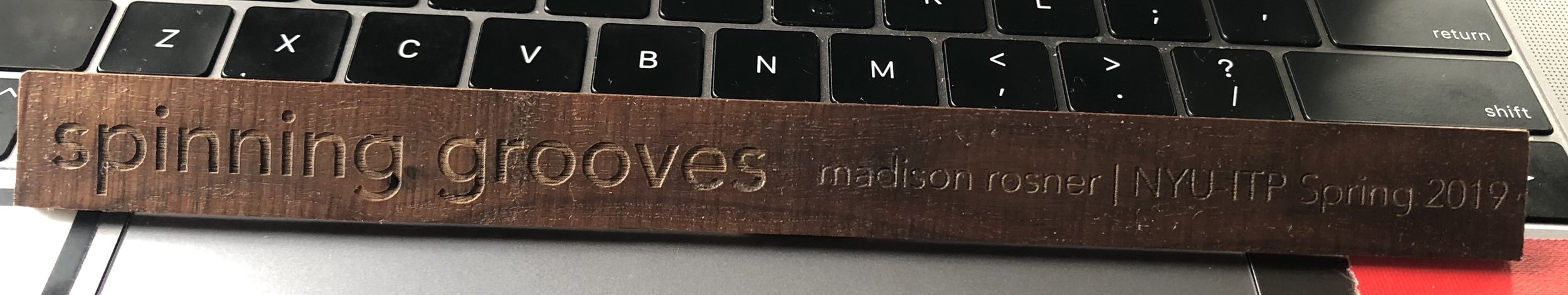

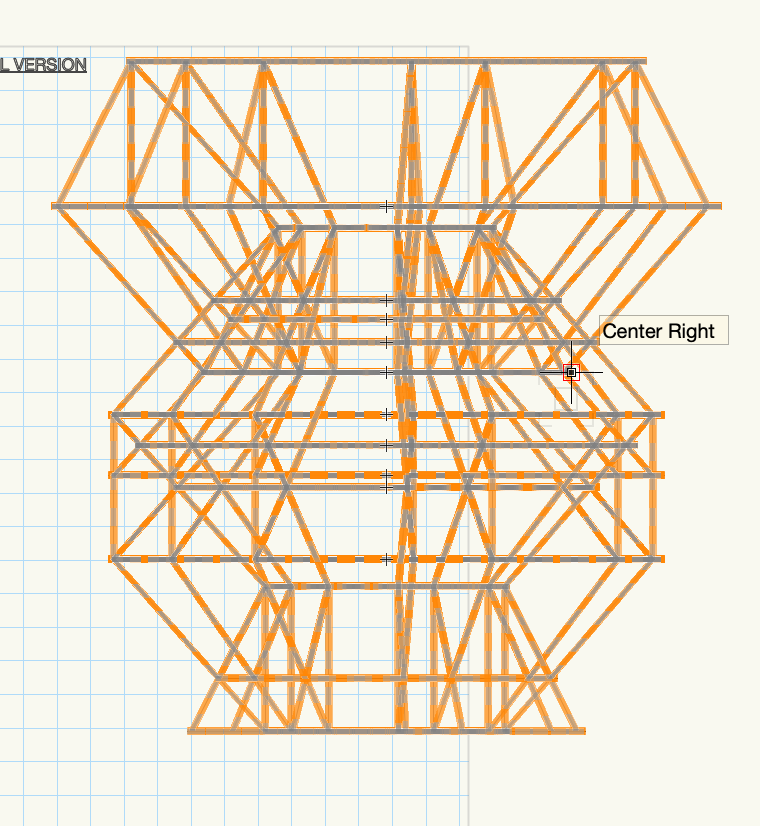

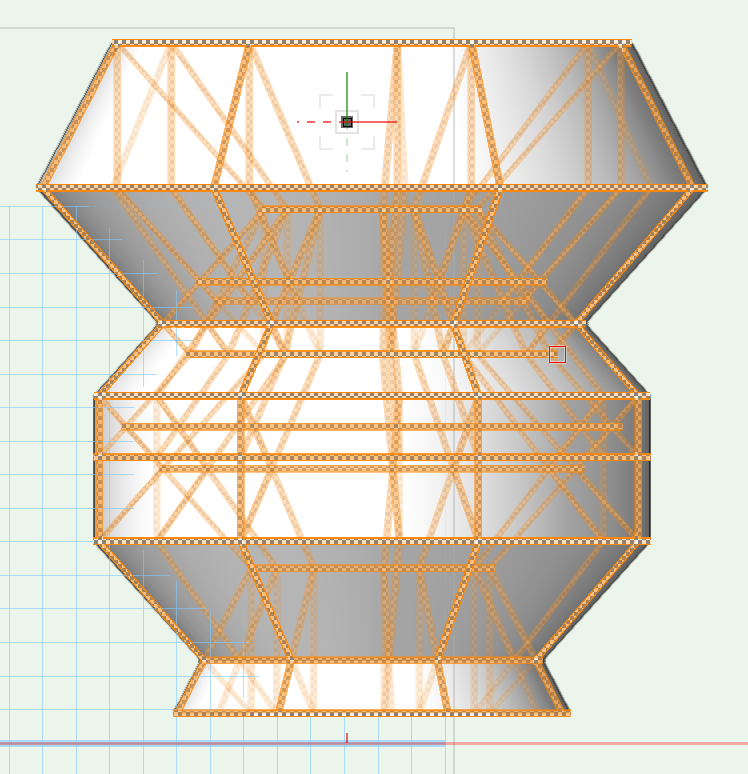

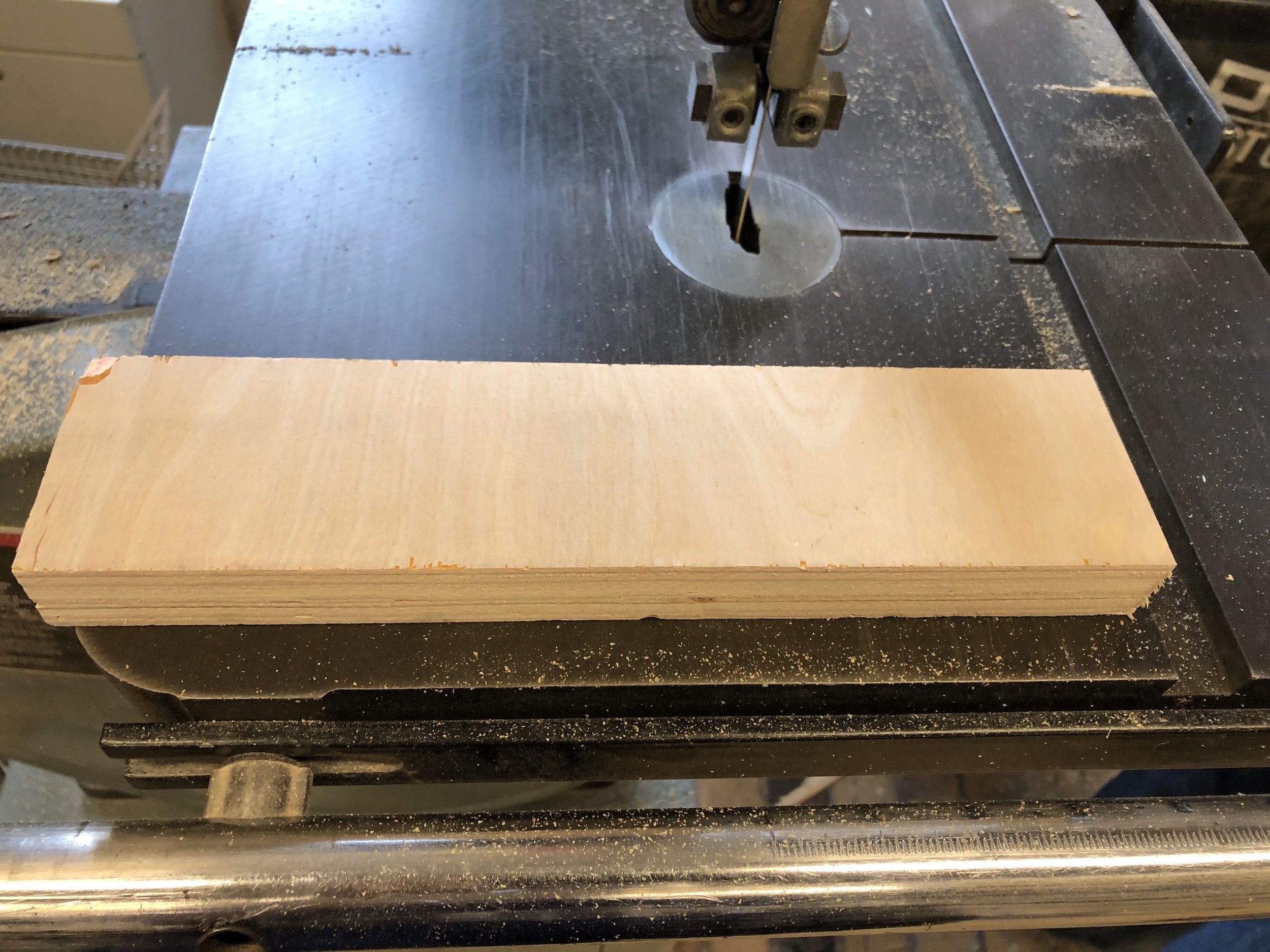

I initially wanted to use this beautiful piece of Norwegian Walnut I found at the Big Reuse in Brooklyn but realized that it would not work on the 4 Axis (because of size) and then didn’t want to entangle myself with the CNC while the other class was building out their finals. I asked John for advice and he suggested a mallet and chisel approach. I had some time so decided to play it out and see what came out of it. I’m just going to say this now. I have so so so much respect for wood workers. This was grueling, yet rewarding. I started out with the drill press drilling some holes to help with the process. This took its toll quickly and I was eager to begin. I decided to drill holders for all the tops at the side and made a presentation sign out of walnut and the laser cutter to display my work. I think I spent roughly 8 hours on this thing. But I love every bit of bump and groove that it has to offer. The chisels were dull and awful but I did it. I made it happen!!

Next came finishing. I love the beeswax I got for the mallet, so just ended up using it on all tops and the board. I think it came out great and class feedback was positive. Because of the nature of imperfections in wood, that was in my favor with detailing out my process and creation. Someone even stated that the tops looked like acorns or other objects that could have easily fallen out of a tree, and some other classmates also commented on how it reminded them of a traditional tea table they grew up with in China. All and all, I’m proud of this one!

x.